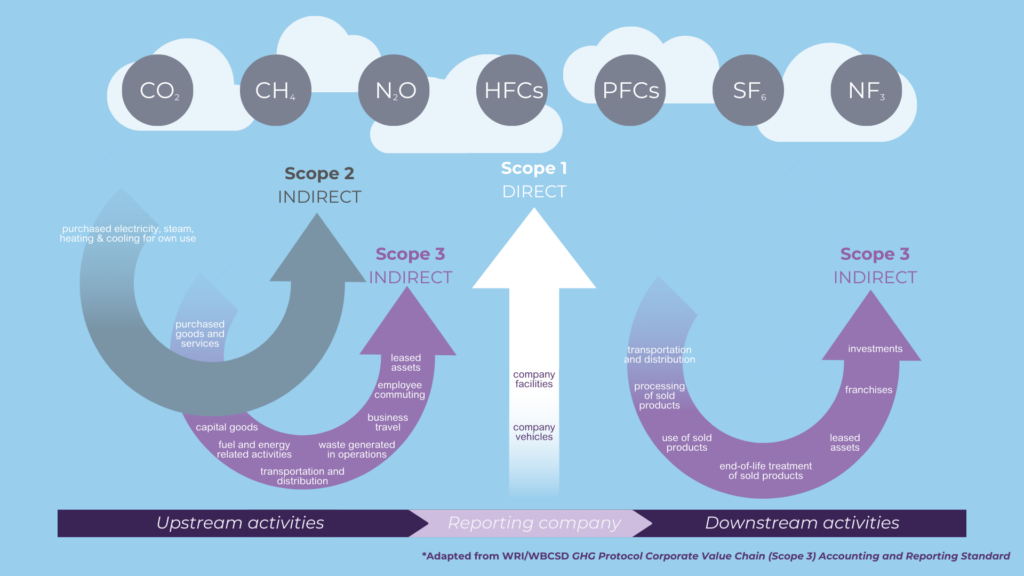

That said, a company’s supply chain emissions make up a sizable portion of their Scope 3 (roughly 90% of total emissions, according to McKinsey & Co.), making them a key component of your emissions reduction strategy!

This comprehensive guide is designed to help you navigate the complexities of supply chain decarbonization from start to finish. We’ll walk you through the process of planning, implementing, and executing a tailored roadmap to achieve your decarbonization goals. By identifying emission hotspots, collecting high-quality data, engaging with suppliers, and leveraging innovative technologies, you can make significant strides toward a more sustainable and resilient future.

Need a refresher?

Our comprehensive decarbonization guide breaks down important terms and concepts for your emissions reduction journey.

Read the full article hereJoin us as we explore practical steps and strategies that will empower your business to not only meet regulatory demands but also lead the way in sustainability.

Building a Supply Chain Decarbonization Plan

Whether you’re feeling pressure from stakeholders or wanting to be an industry leader in sustainability, supply chain decarbonization is a big task. As with any big project or undertaking, breaking it down into smaller, more manageable steps will keep you focused and moving towards your goals. These are the steps we’ve outlined as relevant to any decarbonization journey.

Assessing your value chain emissions

The first step for tackling Scope 3 is mapping your value chain. In a perfect world, this would be a comprehensive list of all the activities in your supply chain, including every supplier/value chain partner and every purchased and sold good or service, each of which relates to a relevant Scope 3 category.

However, whether you have 100 suppliers or 100,000, it is uncommon for any company to have access to this level of data. In fact, a recent study showed that only 6% of companies felt they had full visibility into their supply chain, despite valuing supply chain visibility being a high priority.

If this feels like you, there’s no need to panic; as you work on improving your supply chain visibility, prioritizing your efforts and making educated estimates will take you far.

Getting the lay of the land: identifying potential emissions hotspots

Once you have your supply chain comprehensively mapped out, it’s time to determine a plan for data collection.

Companies often don’t have the time or resources to get high-quality data for every Scope 3 activity along their supply chain; if this is the case for you, it can be beneficial to focus your data collection efforts on suppliers or Scope 3 categories that represent the largest emissions reduction opportunities. After all, your goal is to reduce as many emissions as possible using the least amount of time, money, or resources.

Performing a rudimentary screening of emissions along your supply chain before diving into data collection, while it may seem like extra work, will enable you to quickly pinpoint emissions reduction opportunities and prevents you from wasting your efforts on less useful data.

“What Are Scope 3 Emissions (And Why Should I Care?)”

Don’t miss our article unpacking Scope 3 emissions and their significance here!

Read the full article hereThe Greenhouse Gas Protocol breaks down Scope 3 into 15 different categories; these refer to a broader classification of emissions sources, such as purchased goods and services, transportation, or waste. These categories provide a structured way to organize and understand different types of emissions. Similarly, an activity refers to specific actions or processes within each category that contribute to greenhouse gas emissions. For example, within the “purchased goods and services” category, activities could include the production of raw materials, manufacturing processes, or distribution activities, each of which may generate emissions.

When making these estimations for your suppliers or relevant Scope 3 categories, consider the following criteria:

Size: Will they contribute to your total Scope 3 emissions in a big way?

Influenece: Can you, maybe through longstanding relationships with suppliers or otherwise, facilitate emissions reductions or influence them to take action with or without additional incentives?

Risk: Do these activities pose climate-related risks (whether financial, regulatory, reputational, etc.) to your company? If yes, how significant are these risks to your operations?

Stakeholders: Are these activities viewed as particularly critical or higher priority by key stakeholders in your business?

Sector guidance: Have the activities performed by this supplier been singled out as high-emitters or hard-to-abate by leading organizations?

Spending or revenue analysis: Do the activities performed by this supplier require a high amount of spend from your company, or do they generate a high amount of revenue? **especially important if these high levels of spend/revenue are correlated with high emissions in your estimations**

Sometimes you may not have enough data to calculate exactly how many emissions you’re generating along your supply chain. In this case, you may consider making a spend-based emissions calculation. Environmentally-extended input output models (EEIOs) can be a quick and easy way to estimate the GHG emissions of your supply chain.

Despite their long-winded name, EEIOs are emissions factors that provide cradle-to-gate emissions (from raw materials extraction until it leaves the factory-“gate”) data based on industry or product category, and although this data may not be very granular or customized to your supply chain activities, it is a great way to quickly and effectively screen supply chain activities before investing more time and resources with data collection.

Using the information gathered during the initial screening of your supply chain emissions, you can now develop a plan of action where you can focus your data-collection efforts on the greatest emission reduction opportunities. Having high quality data for the activities that are the most significant to your Scope 3 will allow you to approach emissions reductions more effectively.

Data collection will require a lot of collaboration with your supply chain and with other departments within your company, but remember: perfection is not the goal.

Collect! That! Data!

Once you have developed a plan of action, it’s time to dig into the nitty-gritty of data collection. This will require a lot of collaboration with your supply chain and with other departments within your company (e.g. sourcing, finance, procurement, accounting, marketing, manufacturing, logistics, and more), but remember that perfection is not the goal at first. Strive to collect data that is most impactful, relevant, consistent, complete, transparent, and accurate while keeping in mind that the quality of your data is bound to improve year after year.

It is important to remember throughout this process that not all data is made equal. Industry average emissions factors, for example, will allow you to get a good idea of your emissions output, but may not be accurate or precise to your particular supply chain.

Collecting supplier-specific activity and product-level data will give you the most accurate picture of your own emissions, whereas more indirect forms of data (e.g., emissions factors, industry averages, regional data, etc.) will paint a much more general picture. Environmental product declarations, or Life Cycle Assessments (LCA), which provide information on the lifecycle of a product or material, are commonly conducted by companies and are an accessible way to get supplier- and product- specific data. Meter readings, utility bills, invoices, engineering models, and more can also help you get the most accurate emissions data possible.

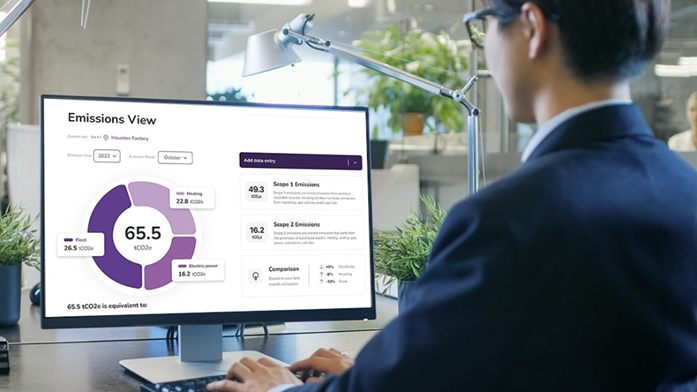

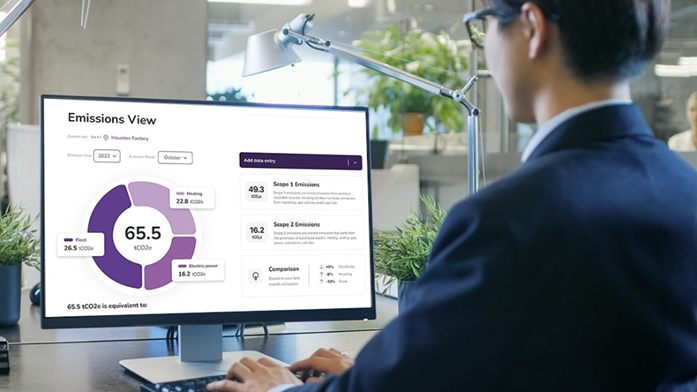

Acquiring this data from suppliers can be tricky; knowing the kind of data you need as well as where to find it can take time. If you decide to do it all manually, it also requires extra communication, coordination, and collaboration with your suppliers and other business units. This is where technology and software, like Zeigo, can streamline and optimize the data collection process to make your life easier. Not only can technology provide a centralized source for data collection, but it can also guide both you and the supplier in terms of the kinds of data you need and can automate the emissions calculation process.

Your comprehensive supply chain decarbonization tool.

Zeigo Activate allows your suppliers to calculate, analyze, and reduce their carbon footprint, all from the same platform.

Learn moreYou may also consider requesting that your suppliers respond to environmental questionnaires such as the Carbon Disclosure Project (CDP). These questionnaires provide good insight into a supplier’s operations and emissions, which makes them a great data source for your Scope 3.

However, if you are unable to get direct data from a supplier, you can use industry averages, financial data, and/or proxy data to help you fill in the gaps.

Sharing is Caring: Let’s Talk about Carbon Emission Allocation

Throughout this process, you may receive data for a specific activity which only partly corresponds to you or your business.

As an example, let’s say you are a fashion company, and you are sourcing only T-shirts from a manufacturer that also makes blouses, jerseys, button-downs, and more. If the manufacturer were to give you the total emissions for all their production, you would need to allocate the portion that comes from T-shirt production specifically. Otherwise, you would wrongfully include emissions from the other kinds of shirts produced by the manufacturer but sold to someone else. To avoid this, you will need to allocate only the emissions you are responsible for.

When allocating, you want to follow a method that most accurately reflects the relationship between the production processes and the resulting emissions and that upholds the values of relevancy, accuracy, completeness, consistency and transparency.

Establishing an emissions baseline: your decarbonization starting point

After collecting your data (to the best of your ability and with the data accessible to you), you will have created an inventory of your supply chain emissions. This is no easy feat! Now it is time to set a baseline. A baseline is representative of what your company’s emissions output looks like under normal operations; in other words, before you begin decarbonizing.

When deciding a base year for this emissions baseline, it is recommended that you select the first reporting year for which you have complete and accurate data on your supply chain emissions; this may not be the case for your first report but aim to establish a baseline as quickly as possible. After all, your emissions baseline serves as a critical “starting point” from which you will develop decarbonization and emissions reduction targets.

Your business will grow and evolve with time, and it can be helpful to set up a recalculation policy in the event you need to change your baseline. Unless you undergo mergers/acquisitions or some other structural change to your organization, however, your baseline will stay the same.

Bullseye: setting accurate and ambitious emissions reduction targets

Now, to the fun stuff: as with any project or initiative, it is important to track performance and set business goals to keep you accountable. Decarbonization or emissions reduction targets can look a few different ways, depending on your emissions portfolio and your business capabilities. For instance, you can have:

- A single target for total emissions across all 3 Scopes

- A single target for total Scope 3 emissions

- Separate targets for individual Scope 3 categories, or

- A combination of targets, for example a target for total Scope 1 + 2 + 3 emissions as well as targets for individual Scope 3 categories.

**Keep in mind that if you choose to create targets for individual Scope 3 categories, they will need to be compared to the same base year.**

“What Does It Mean To Be Net-Zero”

Unpack net zero concepts even further and learn how it relates to your operations in this article!

Read the full article hereEmissions targets should always be precise, feasible, and set to a timeline. Doing this helps you keep yourself accountable while also increasing your credibility to external stakeholders. Here are some questions to think about as you craft your ideal emissions reduction target:

Firstly, will your goal be to reduce the total quantity of emissions within a particular scope (i.e., an absolute target)? or do you want to reduce the emissions produced per unit of something—perhaps per unit of production, or per dollar of revenue (i.e., an intensity target). Absolute targets are more environmentally robust, but do not facilitate comparisons of efficiency the same as intensity targets might. On the other hand, intensity targets are more likely to reflect improvements in performance (as opposed to declines in production) but are less credible to stakeholders because total emissions may rise, even if intensity decreases.

Secondly, will your target(s) be short-term, long, -term, or both? Setting longer-term targets will facilitate larger capital investments, while short-term targets will help you track your progress as you go and keep you accountable.

Third, do you plan to use carbon offsets to reach your goals? Make sure to specify how much of the target reduction will be/has been achieved using offsets and disclose this information in your reporting. Remember also that keeping carbon offsets to a minimum will help ensure that you are taking real strides towards decarbonization in your operations and along your value chain.

Curious about how to use carbon offsets wisely?

Learn how carbon credits can (and should) be a part of your decarbonization strategy!

Read the full article hereAnd (saving the best for last), how much are you planning to reduce? Your target level reflects the potential emissions reduction opportunities within your supply chain as well as your level of ambition. As much as you may want to set a net zero target for next year, setting a target that is too ambitious can damage your credibility with external stakeholders. You’ll want to set a target that strikes a good balance between ambitious and attainable.

Each type of target has its advantages and disadvantages, and it is up to you to decide what type of target will be the best fit for your company.

Emissions reductions

As if the data collection and target-setting weren’t enough, the real work begins with emissions reductions. Because Scope 3 emissions come from outside of your own operations, your role will generally be to assist or facilitate emissions reduction projects rather than manage them yourself. This can present unique challenges, but here are a few tips to get you started.

Supplier engagement: teamwork makes the dream work.

Your suppliers are the gears that keep your company turning— they are a crucial part of not only your sustainability journey but also your business journey. As you engage with suppliers on data collection and eventually emissions reduction, keep in mind that they each are also on their own sustainability journey. As such, you may need to adjust your approach with each supplier depending on their needs.

Your approach to supplier engagement can be coordinated or collaborative. A coordinated approach is one that is more transactional and often risk-driven. Implementing sustainability requirements into procurement contracts and enforcing these requirements via audits are good examples of what a coordinated approach looks like. This approach is most effective with suppliers that provide a generic product or service, are highly substitutable (i.e., there are lots of alternative suppliers you could switch to), and/or only work with you for short periods of time.

Your approach can also be collaborative. This approach is much more flexible and usually involves working together with your suppliers to make shared decisions about emissions reduction plans that are more uniquely tailored to both of your needs/capabilities. This approach is best for discovering innovative solutions to a challenge and is most effective with suppliers who offer a highly specialized product or service, for which there are few alternative suppliers, and if there is a history of positive engagement.

Take a moment to think about the approach you want to take with each of your suppliers. Your approach can (and should) be a combination of the two approaches, but it can be helpful to come up with a plan before diving in.

Beyond your approach to supplier engagement, it is also important to consider knowledge gaps amongst suppliers. You and your suppliers might be at different levels of maturity when it comes to understanding these issues or being equipped to address them. Because of this, you may need to provide incentives to encourage stronger collaboration or provide educational opportunities to help build supplier capabilities (or perhaps your own capabilities) to better address these issues.

Circularity: Redesigning products and processes

When it comes to emissions reductions, a lot of progress can be made simply by streamlining and optimizing existing processes. One model you might want to think about is circularity; circularity refers to the concept of minimizing waste and optimizing resource use by maintaining a closed-loop system. Easier said than done, circularity involves designing products and systems with the intention of reusing, sharing, repairing, refurbishing, and recycling to create a sustainable and circular economy. This approach contrasts with the traditional linear economy, which follows a “take-make-dispose” model.

According to the World Economic Forum, implementing circularity by reusing and recycling products, improving efficiency, and using renewable energy could help you reduce almost 40% of emissions in supply chains without greatly affecting the price of your product. For existing and well-established products, lowering the energy footprint in a suppliers’ operations or increasing the amount of recycled content can help reduce emissions. For new products, it is important to keep sustainability top-of-mind from the very beginning; this can mean using greener materials from the get-go, designing in a way that minimizes waste, reducing product variance, and/or improving the recyclability and repairability of products as they reach end of use or end of life.

Switching to lower-carbon manufacturing processes will also help you reduce your supply chain emissions. Here, a good area of opportunity for many companies involves distribution and logistics. On average, logistics accounts for 7% of global GHG emissions, and companies can achieve an average of 40-50% emissions reductions using solutions that are available today! These solutions include (but are not limited to):

- Optimizing your shipping routes to reduce distance traveled and improve your footprint

- Using higher-efficiency modes of transportation, such as shipping or rail

- Electrifying your fleets to ensure zero tailpipe emissions

- Building warehouses with energy-efficient materials, lighting, and insulation.

- Establishing closed-loop energy systems in warehouses by establishing on-site solar panels and battery storage, etc.

Your comprehensive supply chain decarbonization tool.

Zeigo Activate allows your suppliers to calculate, analyze, and reduce their carbon footprint, all from the same platform.

Learn moreOvercoming Challenges in Supply Chain Decarbonization

You may have realized by now that supply chain decarbonization is no easy feat. On top of all that supply chain decarbonization entails, there are lots of obstacles that make decarbonization much more difficult than it needs to be.

Sustained and sustainable engagement with Suppliers

Getting comprehensive emissions data from suppliers (especially those operating in different countries) can be especially difficult when the supplier doesn’t have much transparency into their own operations. There is no denying that it will take a lot of coordination, education, and collaboration to get the proper data across your supply chain; but there’s no need to lose hope. Establishing relationships with your suppliers, building their trust, and providing them with the resources necessary for them to succeed can make this process smoother and ultimately more successful for you and your suppliers alike.

The Zero Carbon Project, for instance, is a supplier engagement program between Schneider Electric and its top 1,000 suppliers. As part of the program, Schneider Electric provides tools, trainings, and other resources which enable program participants to set and achieve their carbon reduction goals. To facilitate the data collection process, Schneider is leveraging Zeigo Activate, which allows users to calculate, measure, and analyze their carbon emissions.

Additionally, suppliers are also less likely to change their behavior at your request if you make up only a small portion of their business. In the words of the Chief Supply Chain Officer at Unilever, Marc Engel, “You need critical mass to get movement.” In order to reach that critical mass and get the leverage you need to impose higher sustainability standards and trigger transparency across the value chain, you might consider teaming up with other companies that use the same supplier.

For instance, the Energize program (powered by Zeigo Hub!) enables pharmaceutical companies—many of whom share similar suppliers— to come together to both learn more about and participate in the market for power purchase agreements (PPAs). Energize gives suppliers the opportunity to engage in the market for renewable electricity procurement. In doing so, the Energize program helps suppliers address their operational Scope 2 emissions and consequently helps sponsoring companies address their Scope 3 emissions.

Regulatory and compliance hurdles

From environmental legislation to corporate regulations, the landscape of what companies need to disclose or do is constantly changing and growing. It can be hard to know what is expected of you as a company, especially when you don’t know what to keep track of. Some bigger regulations that might apply to you include the Corporate Sustainability Reporting Directive (CSRD) that came out from the EU in 2023 and is expected to affect over 50,000 entities worldwide, or the SEC Climate disclosure rule in the U.S. that came out in 2024.

Most environmental regulations that require you to disclose your emissions limit their requirements to Scopes 1 and 2— for now; but make no mistake, Scope 3 regulations are coming, and, as you have learned in this guide, gaining enough visibility into your supply chain to collect accurate and comprehensive emissions data takes time. The last thing anyone wants is to find themselves ill-prepared when Scope 3 regulations take effect.

Uncertainty over cost and feasibility

You will likely still face a gap in your zero-carbon target even after you have picked all the low-hanging decarbonization fruit. As you reduce your emissions more, the more costly it may get to reduce each next unit of CO2e. Actively engaging with industry leaders to help shape future supply ecosystems can help you make these solutions more cost-effective for you and for others in your position!

You might also face large up-front costs that you won’t reap the benefits of until far into the future—in this case, it can be helpful to explore energy transition and recovery funds made available to you by the public sector.

It can also be helpful to turn to leading organizations that offer free tools and resources throughout your journey.

Silver linings and important resources

Decarbonization involves a lot of moving parts; luckily, technology is a tool that you can leverage along every step of this journey: from data collection to providing tailored educational content to help you and your suppliers level-up their decarbonization game. Look at some of the ways you can leverage technology for the better (or simply listen to the fourth episode of our podcast miniseries in partnership with CleanTechnica which breaks down how software can accelerate decarbonization!):

“Listen: How Software will Transform and Accelerate Supply Chain Decarbonization”

Learn how software can help drive climate action at scale in Episode 4 of our podcast miniseries!

Read the full article here- Data Analytics: Advanced analytics and AI can help in collecting, analyzing, and visualizing emissions data across the supply chain, helping you make better decisions and identify areas for improvement.

- Renewable Energy Integration: Technologies such as solar panels, wind turbines, and energy storage systems can be implemented to ease your transition toward renewable energy sources and away from carbon-intensive power.

- Electric Vehicles and Alternative Fuels: Adopting electric vehicles, hydrogen fuel cells, and biofuels can help decarbonize transportation within the supply chain, cutting down on emissions from logistics operations.

- Energy Efficiency Solutions: Implementing smart energy management systems, energy-efficient equipment, and process optimization technologies can reduce energy consumption and associated emissions in manufacturing and distribution processes.

- Collaboration Platforms: Digital platforms and collaboration tools can facilitate communication and coordination among supply chain partners, many of whom share sustainability goals or can benefit from exchanging knowledge or information on best practices

- Lifecycle Assessment Tools: Software tools for conducting life cycle assessments can help evaluate the environmental impact of products and processes, guiding decisions toward more sustainable alternatives.

“Supporting Decarbonization Efforts in Every Link of Your Supply Chain”

Learn how Zeigo can support businesses small and large throughout their decarbonization journey!

Read the full article hereConclusion

If you’ve made it this far, you have hopefully gained clearer understanding about what supply chain decarbonization means, what it requires of you, and why it matters. Whether you’re at the beginning of your journey learning what Scopes 1, 2, and 3 are for the first time or a seasoned sustainability professional, everyone has something to learn when it comes to the ever-changing landscape of supply chain decarbonization.

Although supply chain decarbonization requires a lot of collaboration between different business units, companies, and organizations, there are ways to simplify this process for yourself and for those around you. Advancements in software—through AI, data processing, and more– have enabled businesses to process, organize, and analyze data faster, more accurately, and more efficiently than ever before. For companies that do not currently have the decarbonization know-how or bandwidth to fully hone-in on your decarbonization efforts, software will serve as an especially crucial asset: automating emissions calculation and tracking, developing emissions reduction roadmaps with minimal effort, and providing educational tools and solutions along the way.

Here are some key takeaways to keep in mind as you go on your way:

- Business Impacts of Climate Change: Climate change poses significant risks to businesses, including supply chain disruptions, regulatory challenges, and reputational risks. Addressing these risks through decarbonization can protect infrastructure, ensure regulatory compliance, and enhance brand reputation.

- Understanding Decarbonization: Decarbonization involves reducing carbon dioxide emissions and transitioning to cleaner energy sources and technologies. This strategy offers benefits such as resilience against extreme weather events, regulatory compliance, operational stability, brand protection, and potential cost savings.

- Emissions Scopes and Net Zero: It’s crucial for businesses to understand emissions scopes (Scope 1, 2, and 3) and work towards achieving net zero emissions. Setting precise and feasible emission reduction targets, engaging with suppliers, and redesigning products and processes are key steps in this journey.

- Overcoming Challenges: While supply chain decarbonization presents challenges such as data collection, regulatory compliance, and cost uncertainties, leveraging technology, collaborating with suppliers, and adopting sustainable practices can help overcome these obstacles.

As you navigate your supply chain decarbonization journey, it’s important to recognize the role you play in addressing climate change. By embracing decarbonization strategies, you are helping your company mitigate risks and lead the way towards a more sustainable future. Leveraging technology, collaborating with stakeholders, and embracing circularity in product design and logistics are pivotal in achieving meaningful emissions reductions.

Resources for the Road:

- World Economic Forum, Net-Zero Challenge: The supply chain opportunity